Method 1: Return to a small straight-line deviation. During the entire process of measuring the angle inclination of a product, there is often a repeated lack of precision. One person uses the same method, but the deviation reaches 0.6 degrees, which is a common occurrence. In many image measurement mobile software nowadays, the collection of straight lines is set to two points by default. For parts with good shape perception and straightness, angle measurement is not easy to cause significant deviation. However, for parts with many burrs, the collection of straight lines using two points produces a very large deviation, and the repeated precision is poor. The angle formed by such straight lines is undoubtedly not ideal for repeated measurements. If everyone uses more methods of finding and returning straight lines to clarify the two sides of the angle, the personal straight line obtained will be closer to the specific border line of the tested product workpiece, and the deviation will be reduced. In addition, the measurement deviation will also be greatly reduced, and the repeatability will be greatly improved.

Method 2: Collect images as long as possible using a straight-line image

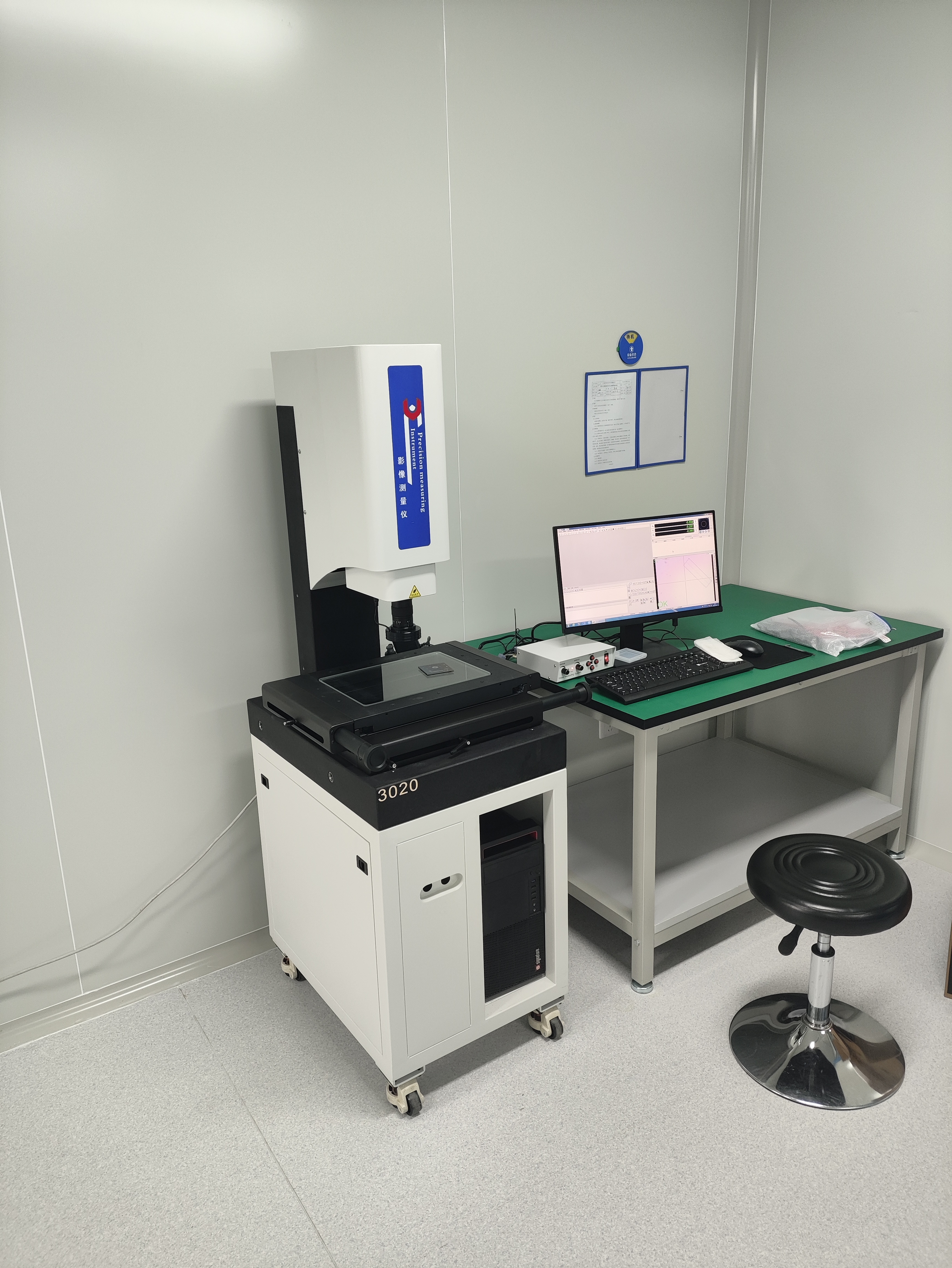

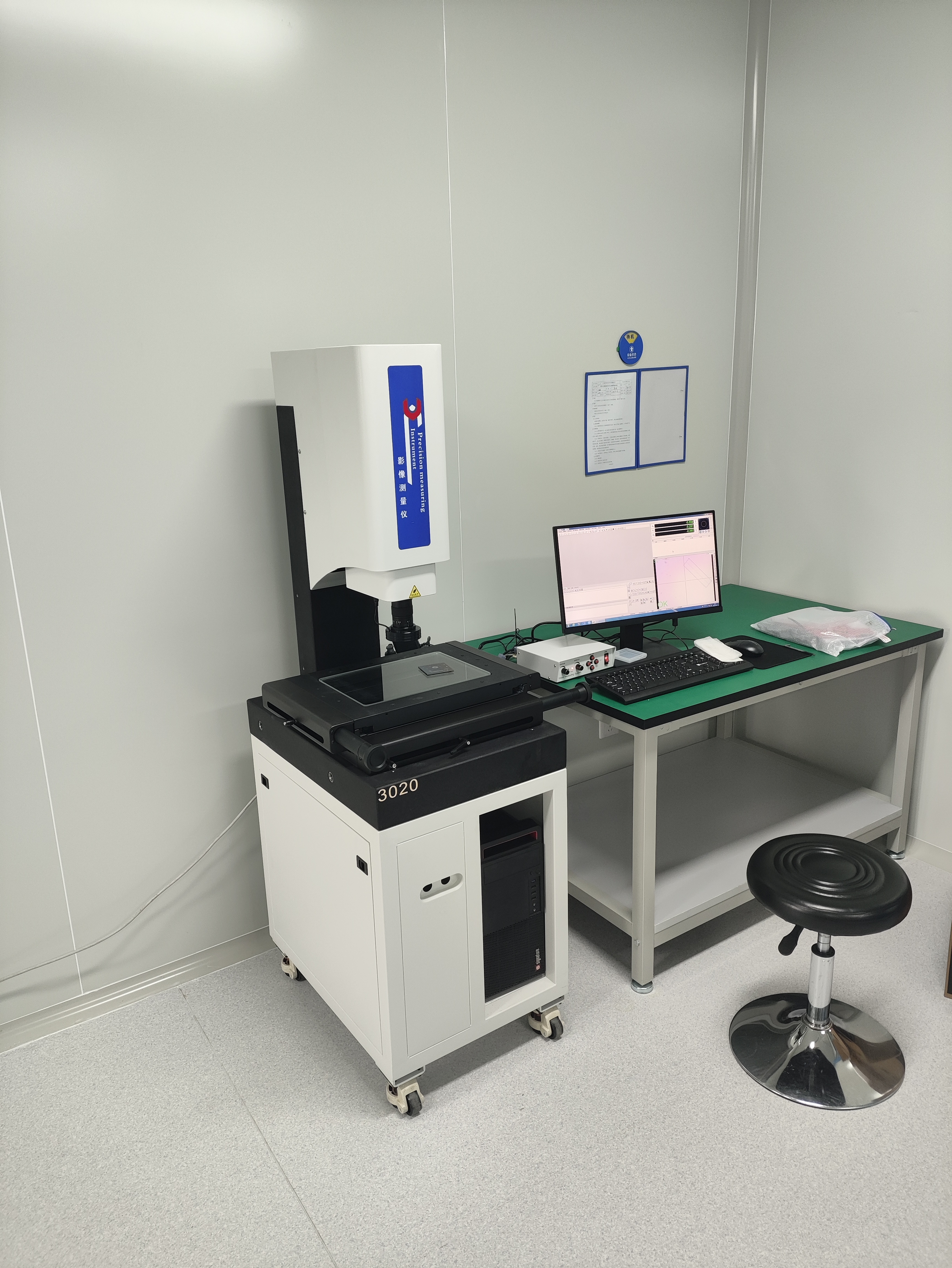

Measuring Instrument. Due to the limited display range on the screen and the large magnification (usually between 0.7-4.5/28X-180X), a portion of the product workpiece specifications displayed on the screen are only in millimeters. Many measurement personnel habitually only display a portion of the collected points and line elements on the screen during inspection. If there is a deviation in the collected points and fewer straight lines are collected, the deviation of the measured angle value will be greater. The longer the straight line, the smaller the deviation of the measured angle value will be. The basic theoretical angle is 30 degrees, and the sampling point deviation is 0.25mm. We can clearly see the harm of the straight line length to the measured value. Therefore, when measuring the angle, we try to collect the lines on both sides of the angle as long as possible. If the display range on the screen is very small, we can move the operating table and take a point at the starting point of the straight line to which the angle belongs, and then take a point at the end station. This way, the measurement angle deviation may be greatly reduced. Angle measurement method three: Increase the magnification as much as possible for many mechanical parts. The measured angle border line is very short, only 3mm, for example, for shaft parts with rounded corners. If we still use a camera lens with a minimum range of 0.7 or 1 for point measurement, the product workpiece imaging will only be 48mm to 120mm, and point deviation will cause significant harm to the measurement value. If we use a magnification of 3 or 4, the product workpiece imaging can reach 240mm to 480mm, and the specific situation of the image edges is more easily observed, and the deviation of the sampling points may be minimized. However, this type of method also causes a lot of trouble. The graphics are too large, and the display information dialog box only displays a small part of the information. However, for inspection personnel who are proficient in practical operations and those who pursue perfect and high-precision quality inspection, this should not be a problem. The anime image measuring instrument developed, produced and manufactured by Dexun Instruments is used in all fields. PCB boards, digital accessories, radio frequency connectors, and each of them in industrial production can complete the production regulations and overall goals according to the inspection of anime image measuring instrument.